Slot Die Coater Design

In proximity coating, the slot die is positioned the coating thickness away from the substrate with a precision backing roll supporting the substrate. The tall lip faces of 0.15-0.30 inch (3.81-7.62 mm) allow the formation of a meniscus and the sharp lip edges allow for release of the adhesive from the slot die. With a slot die, Zwierlein explains you can achieve an attainable wet coating thickness of Slot die can be used to coat thick as well — we’re just highlighting the thin capabilities in this post.).

- Slot Die Coater Design Software

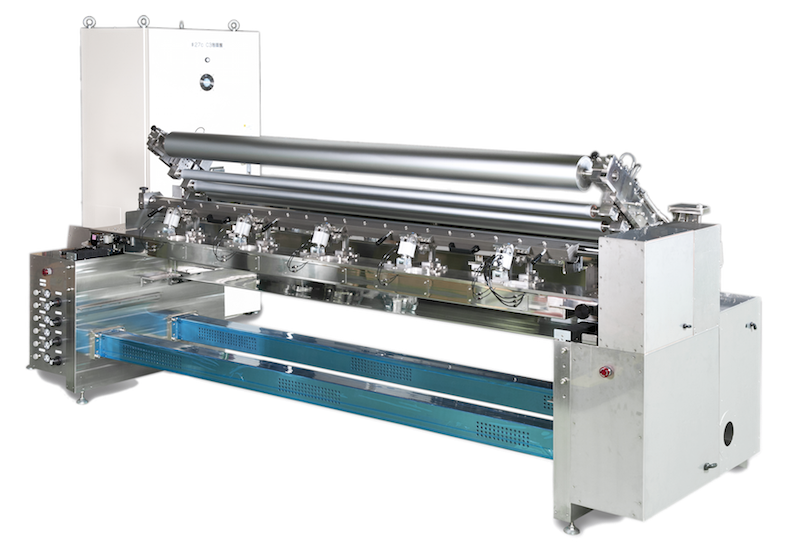

- Slot Die Coater Design Machine

- Slot Die Coater Design Kits

- Slot Die Coater Design Tool

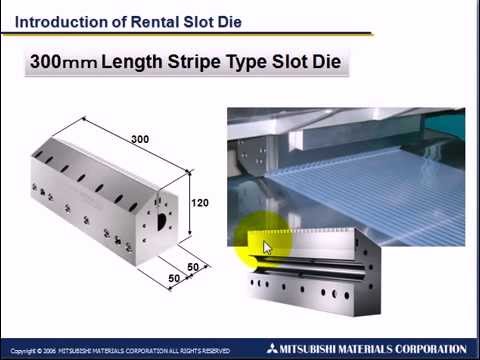

Design, Manufacture and Sales of Slot Coating Dies and patch coaters. Slot die coating technology is a method in which the coating liquid is supplied into the slot die and shaped into a wide and uniform film to deposit on a moving substrate. The technology has a wide variety of applications and is considered to be an extremely powerful means for the production of advanced optical-electronic products. The technology can be extended to simultaneous multi-layered coating for specific products. Many prominent companies that provide slot dies are good at machining and polishing metals, but the most critical issue for making a good slot die is the full understanding of the physical properties of all types of coating solutions, such as fluid rheology, evaporation rates and so on. WCC has extensive experience on managing various types of coating solutions and sound fundamental understanding on the rheological properties of coating solutions. The slot die designed and manufactured based on WCC’s unique experience is cost-effective and can operate with high efficiency. WCC can also make flexible and versatile patch coaters for customers to make samples piece-by-piece up to 500mm wide. WCC promises satisfactory after service on related coating problems. |

Coating Matters Advances in Slot Die Technology for Hot Melt Adhesives, Part 2

- Published: May 08, 2018

In this second and last part of the series, I will cover equipment design and operation.

In Part 1 of this series, I offered an introduction to the advances in slot die coating technology for hot melt adhesives. When it comes to fluid coating onto substrates, the equipment required falls into three areas: extrusion coating, hot melt coating, and liquid coating. What makes these three coating methods the same and what makes them different? I also talked about adhesive rheology (viscosity and elasticity). In this second and last part of the series, I will cover equipment design and operation.

EQUIPMENT DESIGN

So how do you develop the best equipment for such a complex application? Computer modeling. To develop an understanding of this three-dimensional equation of stress relaxation and viscosity response, finite element analysis can provide a window into handling hot melt adhesives properly. Without computer modeling, the manifold design will not consider the complex nature of the adhesive rheology and internal flow characteristics developed in manifold geometries with a slot die. Unlike ambient liquids that have self-leveling capability, hot melt adhesives need to be shaped and molded into the final application of a precision coated substrate.

However, this shaping and molding needs to be gentle enough not to develop additional and unnecessary stresses. The biggest variable controlling how the hot melt adhesive is shaped and molded is the lip opening. To reduce stresses on the adhesive, the lip opening needs to be wide enough to not place undue forces on the polymer melt but narrow enough to distribute the flow evenly across the width of coating. The lip opening is the most powerful variable in coating because it is the only adjustment that is volumetric in nature. As the lip opening is changed the resulting volumetric flow has a cubic effect on forces acting on the fluid. All other equipment variables are linear.

That doesn’t mean that the other equipment variables should be ignored. External to the slot die, the gap between the slot die and the substrate needs to be maintained flat and even to maintain a flat and even coating appearance. Because heat causes the metal to move, die bending adjusters may be required to flatten out the front face of the slot die to match the flatness of the substrate or backing roll. As hot melt adhesives are coated and influence the other equipment, by heating the backing roll, the slot die flatness may need to be further adjusted to match the contours of the steady state position of the equipment. So, unlike ambient temperature liquid coating, hot melt coating may have more variation at start-up. The faster the equipment can get to steady state, the less waste will be developed.

OPERATION

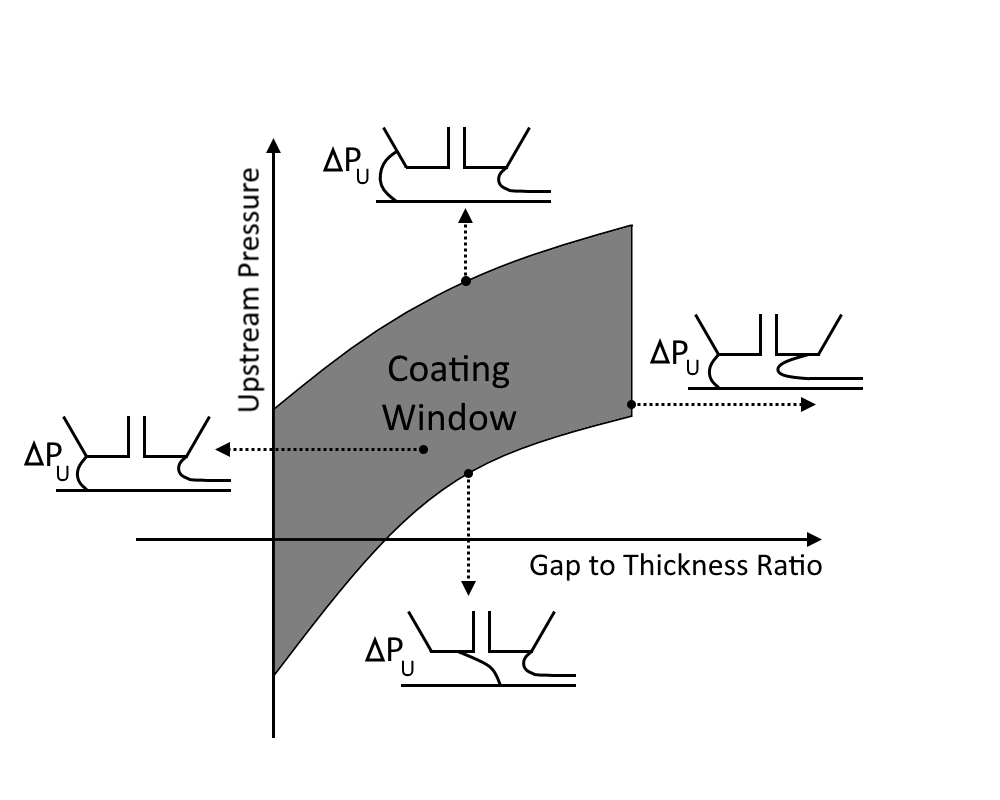

So, once the equipment is at steady state, what do you do if coating defects persist? One common coating defect in hot melt coating is ribbing; where the adhesive is confused as to whether to stick to the substrate or the slot die. In this case, decreasing the gap between the slot die and the substrate may encourage the adhesive to follow the substrate path. If this isn’t enough, the attack angle of the slot die can be adjusted. The attack angle is the rotation of the slot die around the lower corner of the upper lip of the slot die. This rotation will allow the lip faces to have the desired effect of improved meniscus development without the interference of the slot die with other components. When coating rubber bands, there are going to be some limitations to the ability to coat the rubber bands fast and thin.

The current upper limit of speed that I am aware of is 3280 feet/min (1000 m/min). This speed limitation seems to be more associated with cooling capability, but the speed could be lower for a thinner coating because of the stresses involved in the take-away process. This is a multi-variable problem and as the thickness of the adhesive coating decreases, the top speed will decrease also. The coating thickness of the adhesive is strongly connected to the internal strength of the adhesive. An adhesive chemistry can vary widely, and the effect on the ability to coat thin varies with the molecular character of the polymer.

If fillers are added to produce a lower cost adhesive, the coating thickness achievable will rise. It is a balance between raw material costs and processability. For most adhesives, it is safe to assume that 1 mil (25.4 microns) or thicker can be coated. To coat thinner, tests should be run on the adhesive coating capability on a lab or pilot scale line to show proof of concept. I have seen some lower elasticity hot melts coat as thin as 0.5 mils (12.7 microns) successfully. Hot melt adhesives coat thicker also, but there are three main levels that coating can be grouped- > 3 mils (76.2 microns). In this region, a standard flexible lip slot die lip set should be utilized. 1-3 mils (25.4-76.2 microns). In this region, a rotary rod lip set should be utilized. < 1 mil (25.4 microns). In this region, a rotary rod lip set should be used, but is not guaranteed to have success. In the thicker regime, coating with a standard lip set would allow for a proximity coating technique. In proximity coating, the slot die is positioned the coating thickness away from the substrate with a precision backing roll supporting the substrate. The tall lip faces of 0.15-0.30 inch (3.81-7.62 mm) allow the formation of a meniscus and the sharp lip edges allow for release of the adhesive from the slot die. When the coating required drops below 3 mils (76.2 microns), a rotary rod lip design should be utilized to have streak free coating.

Without the rotary rod lip design, the lip opening and slot die to substrate gap starts to narrow to the point that adhesive gels or char can develop streaks that are persistent. The way a rotary rod lip set works, the slot die lip face is actually pushed into the backing roll to develop a deflection in the roll. This deflection creates longer path for the substrate to follow, resulting in a slip phenomenon where the adhesive gel or char that would normally get stuck in the narrow gaps clears the path. The backing roll needs to be made of rubber to allow for this deflection. As a general rule of thumb, the thinner you coat, the harder the durometer the rubber should be. It is common to see a 70 Shore A durometer roll for 3 mils (76.2 microns) of coating and a 90 Shore A durometer roll for 1 mil (25.4 microns) of coating. As presented in the explanation of the rotary rod lip design, the slot die itself is not the only equipment contributing to the ability to coat precisely. The backing roll, fluid delivery system and slot die positioner all provide some functionality to the success of adhesives coating.

In addition, the web handling, tension control and stability of the roll-to-roll coating line can reduce variability or contribute to coating defects. For all equipment involved it is critical to maintain temperature evenly. Variation in temperature translates into variation in rheological characteristics of the adhesive. As the rheology varies, flow varies and the equipment needs to be adjusted to compensate. When at all possible, get to steady state and stay there as long as possible.

CONCLUSION

Slot Die Coater Design Software

When it comes to fluid coating, there are three options to consider. If the application lends itself to hot melt adhesive coating, keep in mind that you are working in the one area that is the cross section of extrusion and liquid coating. This complex area of operation has a lot of potential, but you need to do your homework to be successful. Understand the limits of the adhesive. Understand the limits of the equipment. Develop the best adhesive for the application and then model the equipment to optimize performance. Hot melt adhesive coating is growing in popularity, so the more you can develop a knowledge base the farther ahead your company will be.

Slot Die Coater Design Machine

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.